Balancing water supply

GRI 303-1

EVRAZ business operations require a significant volume of water on a daily basis. As water is an essential part of our production processes, we seek to develop efficient water management practices vis-à-vis water intake, its rational use via recirculating, and the treatment of wastewater.

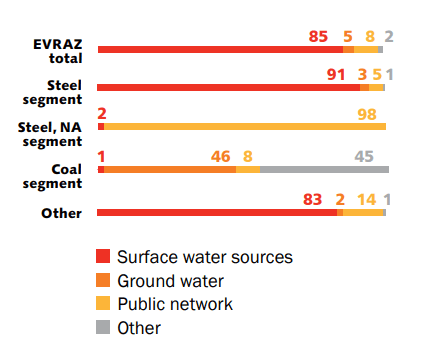

Freshwater resources are having significant environmental and economic importance for the world. The Group consumes fresh water from surface water sources, ground water wells and public water networks for production processes, equipment cooling needs, fire safety as well as for drinking and household purposes.

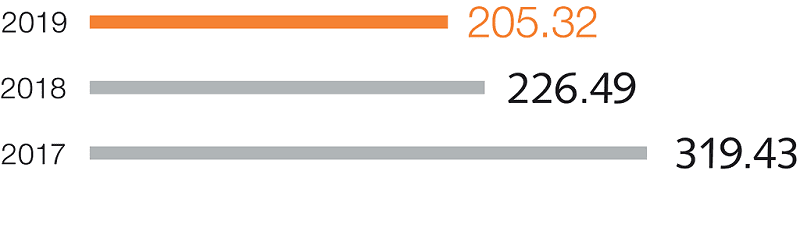

Based on our environmental targets we need to achieve a fresh water consumption level of 207 million m3 by 2022. In 2019, the total volume of fresh water consumed for production needs stood at 205.32 million m3, which was 21.17 million m3 lower than in 2018. This reduction happened largely as a result of asset exclusion and successful completion of a number of modernisation initiatives.

Our key steel making integrated plants has been designed in the middle of 20th century with “open” water cycle system; they contain electric power plants that provide heat and power for production needs and to the local cities. They consume the biggest share of fresh water. The major part of this volume is used for cooling needs. We have target to minimise our fresh water consumption by “closing” water recycling systems. Potentially we want to exclude all water discharges (68.9 mln m3 in 2019), but it will take time. For example, EVRAZ ZSMK is implementing the long-term “Water” programme over 2018–2022, to bring about a 12 million m3 decline in total discharges by 2022.

GRI 303-3

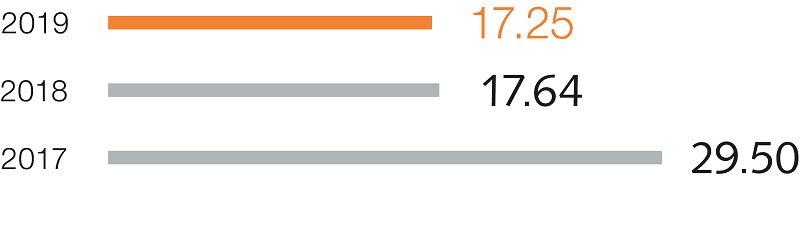

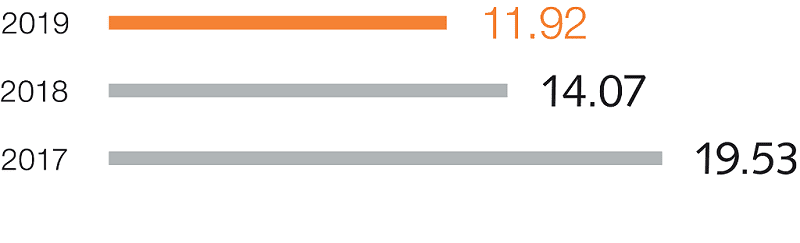

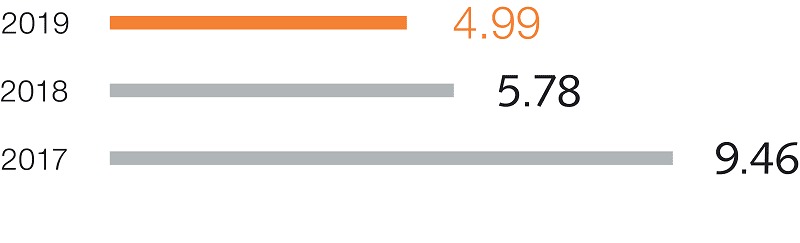

The water intensity rate (m3 of water used per tonne of steel cast) dropped 15.3% in 2019 and stood at 11.92 m3The figure comprises data pertaining to EVRAZ ZSMK (excl. Evrazruda), EVRAZ NTMK, EVRAZ DMZ, EVRAZ Inc. NA, and EVRAZ Inc. NA Canada.. Also, the figure for fresh water withdrawal intensity (m3 of water used per consolidated revenue) also fell by 2.2%, and reached 17.25, compared with 17.64 in 2018.

GRI 303-4

Over 93.6% of total fresh water is used by EVRAZ NTMK, EVRAZ KGOK, and EVRAZ ZSMK (including Evrazruda). Over 86.1% of their needs are covered by surface water, including water from rivers, lakes, and reservoirs.

GRI 303-3

Total water consumption at these sites stood at 201.01 million m3, with fresh water making up over 95.6% of this demand.

Promoting and developing water recirculation is an essential part of reducing fresh water consumption. At our assets, 93.3% of water used in production is recirculated, and EVRAZ tries to raise this amount by supporting upgrade projects for treatment units, which boost water use efficiency.

The Coal and Ore mining sites of the Group have to pump mine (or quarry water) out of mines and open pits for safety reason. Mine water is produced when subterranean waters of various horizons mix and interact with the mine atmosphere and the rocks uncovered by mining excavations. Unfortunately, we cannot 100% control or forecast the volume of such water because it depends on the natural reasons. We always look for opportunity to use mine water for production needs instead of fresh water, but the volume of such water is higher than our mining assets can consume and majority of our mines are situated in remote places and cannot share its excess of water with other water consumers. In 2019, only 21.2 mln m3 (or 27%) of mine water was used for production needs instead of fresh water, the rest of pumped out value 57 mln m3 (73%) was treated and discharged into the water bodies.

Project: Reduction of discharges at EVRAZ ZSMK

Stakeholders: local communities

One of the “Water” programme’s objectives is to reduce fresh water consumption at the pump and filter station of the rail and beam shop. Previously, warm wastewater from the rolling mill was replaced with cold river water. However, after evaluating the efficiency of coolers and the costs involved, it was decided to build an open-type fan cooling tower. This reduced the river water intake and halted discharges from the factory shop.

Thanks to the water protection programme, EVRAZ ZSMK in 2019, reduced discharges into the Konobenikha River by 900 thousand m3 compared with 2018.

Value for stakeholders: a clean river.

Value for EVRAZ: public trust, enhanced reputation, absence of fines.

GRI 303-2

We work in close cooperation with regulatory bodies to obtain discharge permits. During the preparation of the supporting documents required to obtain a permit, we scrutinise the initial characteristics of the water body, the chemical composition of wastewater, available capacities and the technical equipment at treatment facilities, in order to calculate the volume of effluent that will have no harmful impacts on the quality of the water in the basin.

Project: A doubling in the size of treatment facilities at the Raspadskaya mine

Stakeholders: local communities

The upgrade of mine treatment units at Raspadskaya has been a landmark project for the Group. A large-scale renovation, with full technical re-equipment, was completed in the middle of 2019. The total project investment was US$2.5 million. The grand opening of the new units took place as part of the “Green Living Room” regional environmental education event.

The treatment facilities previously processed 800 m3 of water per hour; after the renovation their capacity grew significantly, to 1,800 m3, a 225% rise. The discharge of suspended solids dropped by 62%, and oil products – by 65%.

The project enables us to reuse most of the treated water for the needs of both the Raspadskaya mine and the preparation plant, and discharge the remainder into an open source, as the quality of the wastewater meets the highest standards.

Value for stakeholders: clean rivers.

Value for EVRAZ: public trust, enhanced reputation, absence of fines.