Boosting energy efficiency

Consistently reducing energy consumption is one way that companies can lower their environmental impacts. For many years now EVRAZ has been working hard to improve energy efficiency at its facilities.

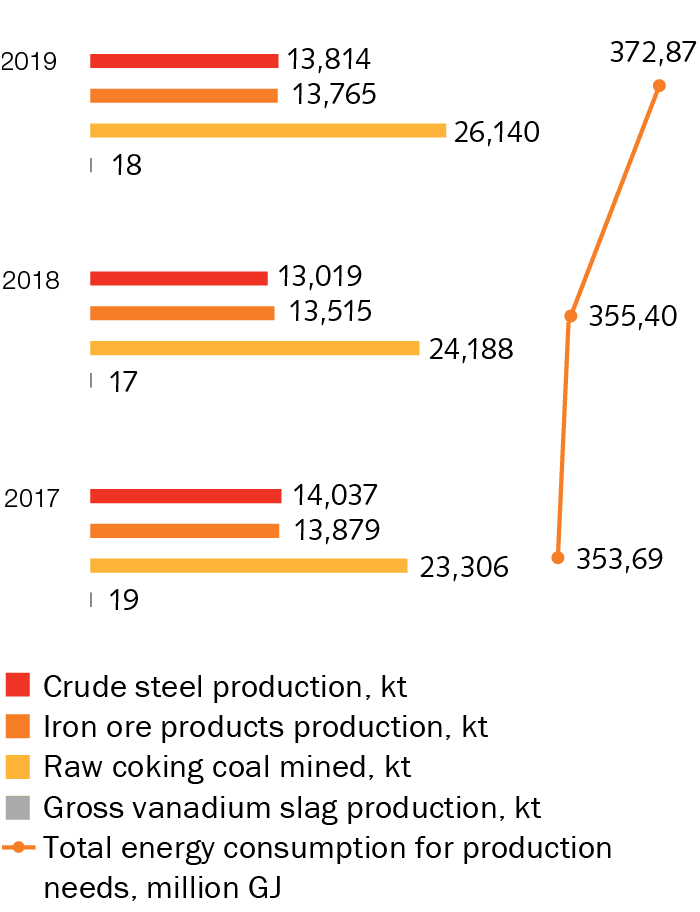

EVRAZ energy consumption, like any major production facility, rises with the increase in production output or the release of energy intensive metal products. In addition, the scope of the Group includes power generation facilities for own needs. Thus, in the Steel segment, more than half of the electricity consumed is provided by own power generation (≈4 billion kWh), and the self-sufficiency of steam and hot water is over 90%.

On the one hand, own processing of one type of energy resource into another reduces the cost of energy resources consumed, but, on the other hand, increases the overall EVRAZ energy consumption, especially during cold periods.

Energy intensity level of the Group’s enterprises is one of the key drivers for our energy efficiency programmes. Measures taken to boost energy efficiency include:

- Minimising energy losses at current production sites, by introducing advanced technologies and global best mining and steel industry practices

- Using renewable energy resources

In 2017, EVRAZ NTMK became the first EVRAZ enterprise to adopt the Energy Policy, which sets forth basic energy conservation principles and areas for improving energy efficiency.

GRI 302-1

Besides, EVRAZ NTMK received certification under the ISO 50001 standard, and applied Energy Management System Guidelines (RENM 102–31–2017).

In 2019, the senior management of the Group put the focus on strengthening the energy management system at EVRAZ. Specially invited professional consultants worked at the Group enterprises, and then presented an objective report and the necessary steps to reduce energy consumption on an ongoing basis. We decided to allocate and strengthen the vertical management of the energy management system at production facilities in Russia. Special checklists were introduced in EVRAZ segments to assess the implementation of tasks to improve the energy efficiency of facilities, based on five elements of the EVRAZ business system.

For a number of years, the Group conducted external benchmarking in cooperation with other industry leaders for two most energy intensive production facilities – EVRAZ ZSMK and EVRAZ NTMK, energy consumption at which is more than 85% of the Group’s total. The accumulated information allows to set ambitious goals and identify opportunities for future improvements. EVRAZ will continue to analyse the best available technologies and plans to create individual goals for each production chain. The Group also actively works on integrating energy efficiency criteria into procurement processes and investment activities.

The goal of reducing the energy intensity of production at EVRAZ enterprises is achieved by implementing Energy Efficiency Improvement Programmes, which include initiatives to be implemented over the next five years. The Group encourages its employees to come up with new initiatives and ideas. Special boxes are installed at EVRAZ entities to collect suggestions, the best offers are then tested and implemented at our facilities. Each EVRAZ facility has its own organisational structure to review potential projects (scientific and technical councils). Each year initiatives and projects are specified for budget financing and monitoring of their successful implementation.

During the reporting period EVRAZ enterprises did a great job to enhance their energy efficiency. For example, at the Siberia Region of the Steel Segment (EVRAZ ZSMK), as part of its operational activities energy efficiency measures were implemented with a total spending of US$6.3 million, growth points were identified, and two energy-related investment projects were completed.

Case study

In September 2019, EVRAZ ZSMK held the “Growth Points” event, a brainstorming session featuring internal and external experts to generate hypotheses for enhancing energy efficiency. During the event specialists discussed such issues as converter gas utilisation, construction of top-pressure recovery turbines, and construction of a gas turbine unit using blast-furnace gas. These hypotheses will be closely studied by working groups at enterprises in order to assess their applicability.

The Group has plans to organise this event at EVRAZ NTMK in 2020.

EVRAZ is also carrying out studies to ascertain which renewable energy sources are most suitable for its operations and strives to identify projects that are attractive both from an economic and environmental standpoint.

Case study

In 2019, EVRAZ North America, Xcel Energy, and Lightsource BP announced that they had agreed to develop a new 240-megawatt solar facility in Pueblo. This long-term agreement is key to our investment in Colorado’s new sustainable economy.

The project will be located at the EVRAZ Rocky Mountain Steel property in Pueblo, and the launch is scheduled for the end of 2021.

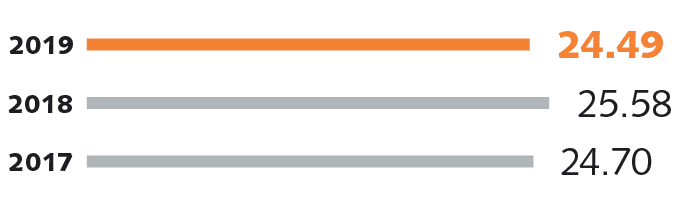

At the end of 2019, EVRAZ achieved an energy intensity level per tonne of steel cast of 24.49 GJ/tonne. The decline was due to the set of organisational and technical changes implemented during the year at all EVRAZ enterprises.

GRI 302-3